Endurance has the capacity to support the Customers in all the project phases, from the design to the mass production, offering prototype services and a large experience to industrialize in the best way the new components.

Research & Development

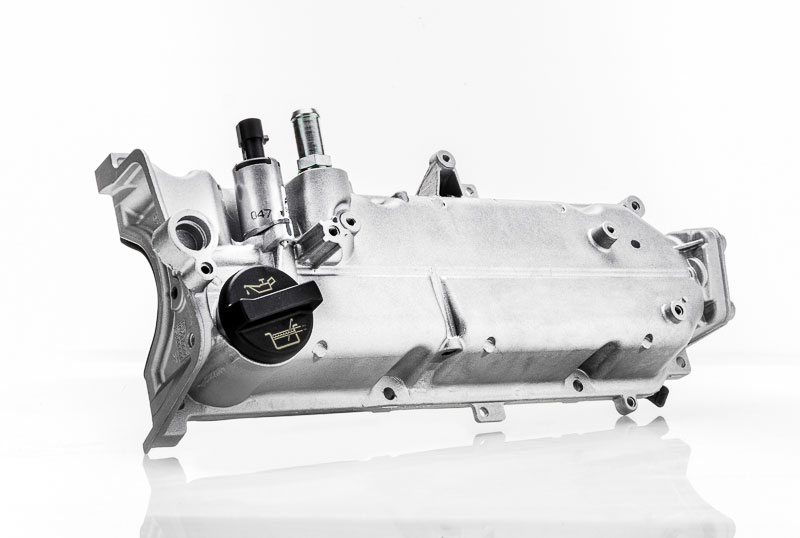

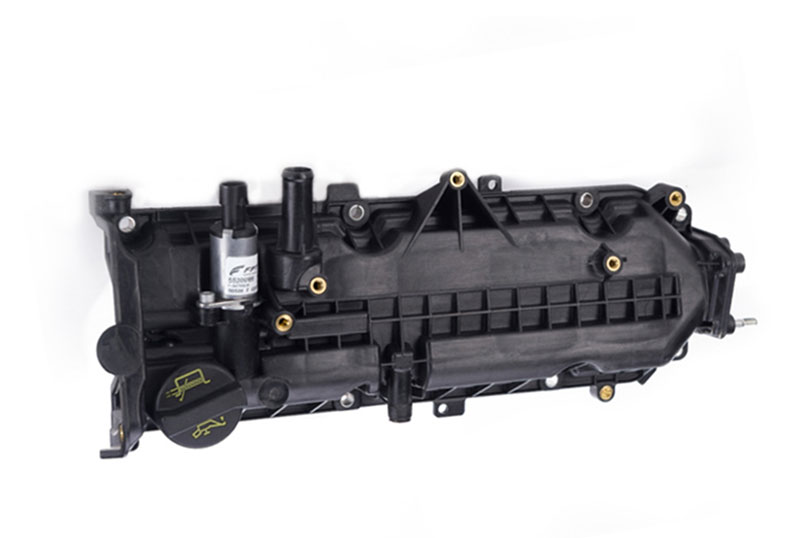

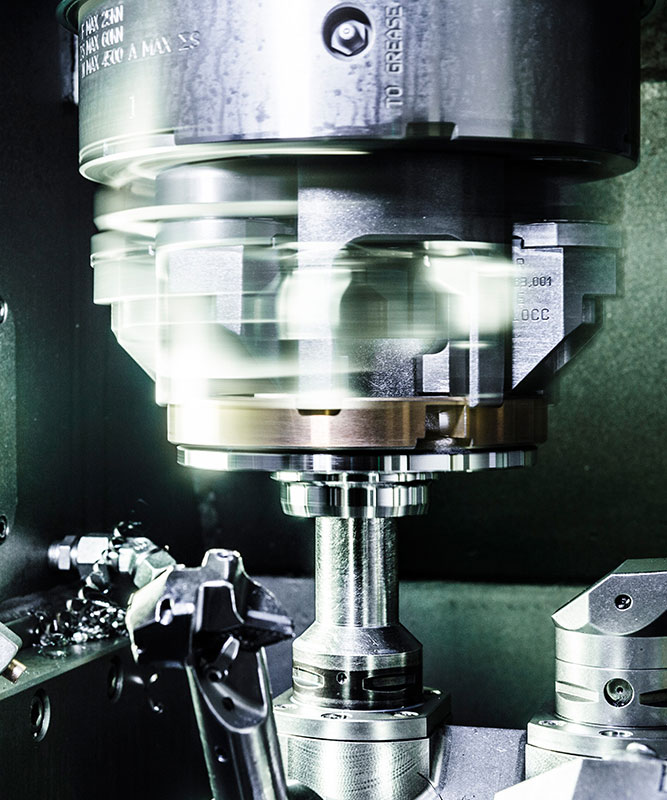

Castings & Machining

FEM and Casting analysis

About casting process analysis, Endurance has in house the capability of developing HPDC components choosing the best process set-up.

Our experience combined with the last software generation allow us to optimize the product design to minimizing the risk of porosity, shrinkage and deformation.

During the development phase we have the possibility to compare the casting simulation with the real result using our CT scan machines in order to refine and to improve our software settings.

Design

Activities focused on: Clamping fixtures, Specific gauges, Leakage test benches and Assembling instruments

Construction

All fixtures made and tested internally using dedicated machines.

Prototyping

Prototypes made with Computer Aided Manufacture system (parts used by Costumers for engine tests validation). We have in-house cleanesses test equipment to perform analysis of the washing performance of our washing machines.

Injection Molding

Since 2010 Endurance Overseas has approached to a diversification process in order to introduce injection molding technology to widen its capacity to provide complete solutions. Based on a current ongoing projects injection molding simulation methods have been introduced (Moldflow analysis) with FEM analysis.

The experience in engine parts and injection molding technology allows Endurance Overseas to be the proper partner for design and production of native engine plastic components or re-engineered parts from metal to plastic.

DRIVELINE COMPONENTS

in Endurance Adler

Transmission

• 3D Modeling, 2D Drawing

• Fast prototyping

• Vehicle testing and transmission fine tuning

• On-board data acquisition (System provided by Alma Automotive)

• Data analysis system (Wintax4):

• Complete transmission analysis

• Focus on launch analysis

• Dyno bench Testing (endurance tests)

• Clutch characterization according to SAE2 normative

• Dedicated test with SAE2 tooling:

• Drag characterization

• Anti-hop characterization (static and dynamic)

• Test bench

• Static µ (Torque) Test

• Core Plate lug Strength

• Damper Characteristics

• Damper Endurance

• Stiffness (plate, pressure)

• Stiffness (boss, clutch)

• Clutch, SPRG Endurance Test

• Clutch, SPRG Hot set Test

• Burst test

• Axial strength of riveting

• Road testing & Clutch fine-tuning experts

Endurance Adler R&D division provides the more specialized clutch fine-tuning services available in the market:

Road testing provided by clutch experts with 30+ years of experience

On-site fine-tuning service at the customer’s R&D facilities

Fine-tuning service at our factory in Rovereto and in testing tracks of the customer’s motorcycle

Engineering consultancy and development of the entire transmission system and clutch and gearbox actuation

Suspension

• 3D Modeling, 2D Drawing

• Implicit nonlinear analysis

• MBD-rigid Body dynamics

• Design optimization

• Fatigue analysis for fork pipes

• Nonlinear hyper-elastic analysis

• Prototype assembly shop

• Performance testing

• Fatigue Testing

• Durability testing

• Vehicle testing tracks

• Suspension tuning truck

ICARO Project

ICARO (Industrialization of Cast Aluminum products), with the patronage of the Piedmont Region, is a project started in the R&D Center in Chivasso (Italy) with the aim to test new processes and develop innovative solutions to be transferred to mass production and to train operators in new technologies.

Here some examples of activities tested:

LIGHTER NEAR NET SHAPE CASTING

TESTING FOR CERAMIC CORE & METALLIC FOAM APPLICATION

HIGH TECH CLEANING

NVH VALIDATION PROCESS IMPROVEMENT

The project refers in particular to the Regional Operational Programme “Regional Competitiveness and Employment”.

((E.R.D.F. 2014/2020 Action I.1b.1.1. – “Support for the economic exploitation of innovation through experimentation and the adoption of innovative solutions in processes, products and organisational formulas, as well as through the financing of the industrialisation of research results”) – Legal basis: EU Regulation n. 651/2014.

Announcement: “IR2 ” Industrialization of Research Results

Project codes: 309/2 and 309/3

The total Budget is approximately Euro 5,270 thousand, of which ERDF funding of a maximum of Euro 1,494 thousand.

The European Commission has approved, under EU State aid rules, an Important Project of Common European interest (“IPCEI”) jointly notified by Belgium, Finland, France, Germany, Italy, Poland and Sweden to support research and innovation in the common European priority area of batteries.

The project will involve 17 direct participants, mostly industrial actors, including small and medium-sized enterprises (SMEs).

The direct participants will closely cooperate with each other and with over 70 external partners, such as SMEs and public research organizations across Europe.

Endurance is willing to exploit its technological know-how, developing innovative battery modules housing for automotive application designed for easy assembling/dis-assembling and re-use in other fields of application, for lower environmental impact and better materials management and recycling.

Driving sustainable aluminium

The SALEMA project is a combined strategy of decreasing the critical raw material dependency (from magnesium and silicon) and creating a sustainable economy in the aluminium manufacturing industry of Europe. The electric automotive sector needs high-performance, sustainable aluminium sources, that is only possible by the generation of a new aluminium ecosystem.